Channel plates and fabrics are the essential parts of a machine called a channel press. These adaptable bits of gear have been being used since the 1800s, however were for the most part used to make mud. As of now, they effectively separate fluids from solids for the mining, food, and drug ventures, yet their chief use is inside wastewater treatment plants. Here we will depict the treatment of wastewater and afterward separate the particular job that channel plates and materials play in that cycle.

An Overview of Why and How Wastewater Is Treated

Wastewater is characterized as a liquid, which contains broke up and suspended solids that is ousted from ranches, manufacturing plants, and homes. Wastewater might try and be viewed as contaminated in the event that it conveys synthetic substances, modern waste, or poisons. In light of the potential damage wastewater can cause, it should be treated prior to being delivered once more into the climate to participate in the water cycle. Now and again, wastewater might try and be treated for the express reason for reuse.

There are three moves toward in general treatment that most wastewater treatment plants perform on fluids prior to permitting their re-discharge or reuse. These means are essential treatment, optional treatment, and tertiary treatment. While the last option steps include the utilization of natural organic entities or synthetic compounds separating matter filter plate that can’t be stressed from the water, essential treatment includes the evacuation of strong silt in the wastewater through the channel press.

How the Filter Press Facilitates the Primary Treatment of Wastewater

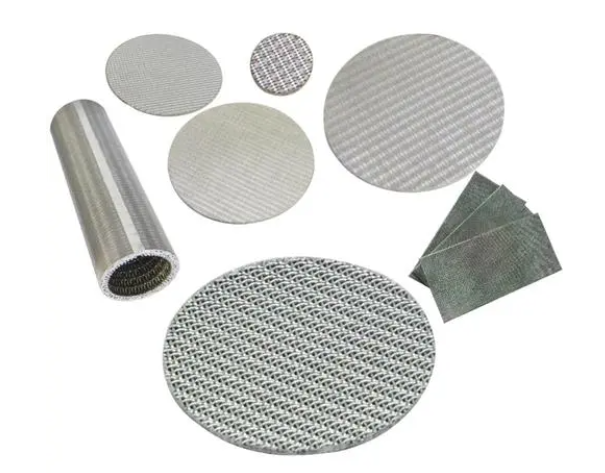

In activity, slurry (the mix of fluids and solids) is siphoned under tension into the machine. A moving part holds a few channel plates together utilizing a water driven framework. The channel plates contain material focuses that go about as strainers.

As the slurry goes through the plates, the fluid piece goes through these sifters and the solids are abandoned to frame what are known as “cakes.” Depending on their creation, wastewater cakes are then disposed of, or they move onto additional handling that consolidate wash mixers, warming, vacuum, and air, so they can be securely discarded in landfills.

Among various kinds of presses that are equipped for taking care of the treatment cycle, the plan utilizing channel plates and fabrics stays the most central and productive. The capacity of the hardware is undisputed, as these machines can eliminate as much as the vast majority of strong byproducts and slime from liquid. The utilization of these presses speeds up the general treatment process, and furthermore diminishes the “biochemical oxygen interest” or “Body” of the liquid, meaning how much oxygen polished off by microorganisms separating the natural waste in the water (optional treatment). For this large number of reasons and that’s just the beginning, the almost 200-year-old innovation is currently a pillar of the wastewater treatment industry.