There are several types of block making machines available, including manual, semi-automatic, and fully automatic machines. Manual machines require more labor and effort, while fully automatic machines require minimal labor and can produce a higher volume of blocks.

Another type of block making machine is the mobile block making machine, which can be easily transported to different sites for on-site production of blocks. There are also specialized block making machines for producing specific types of blocks, such as interlocking blocks or hollow blocks.

There are several types of block making machines available in the market. Here are some of the common types:

- Manual block making machine: This is a basic type of block making machine that requires manual operation to produce blocks. It is often used for small-scale production or in areas with limited access to electricity.

- Semi-automatic block making machine: This type of machine requires some manual operation, but some functions, such as material feeding and block shaping, are automated.

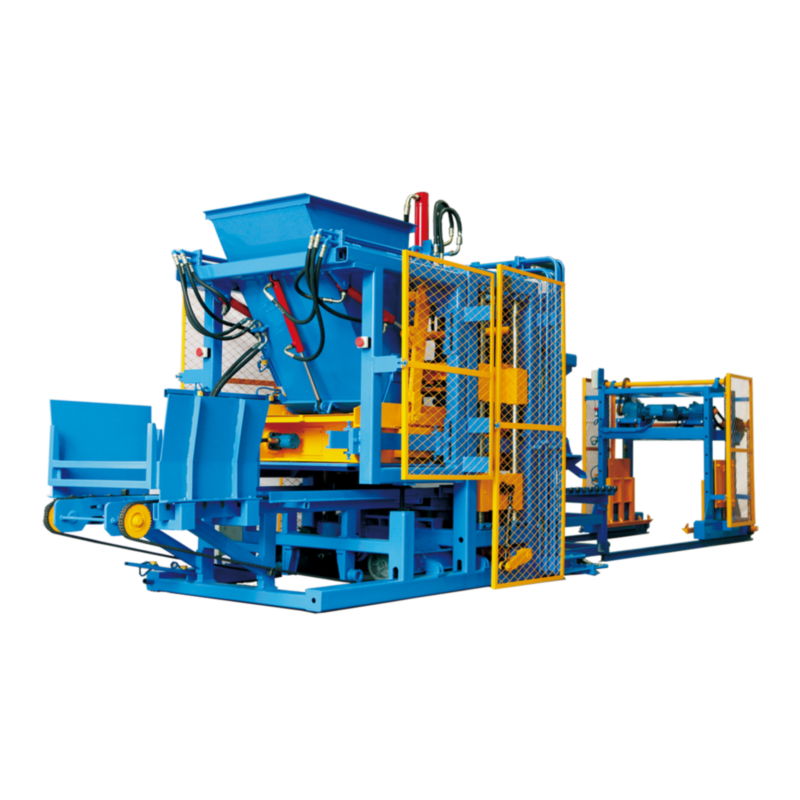

- Fully automatic block making machine: This type of machine is fully automated and requires minimal manual operation. It can produce a large number of blocks in a short period of time and is suitable for large-scale production.

- Hydraulic block making machine: This type of machine uses a hydraulic system to compress the raw materials and produce blocks. blocks making machines It is known for its high production capacity and precision in block shaping.

- Concrete block making machine: This type of machine is designed specifically for the production of concrete blocks. It can produce different sizes and shapes of blocks by using different molds.

- Hollow block making machine: This type of machine is used for producing hollow blocks, which are commonly used in construction for their lightweight and insulating properties.

- Interlocking block making machine: This type of machine is used for producing interlocking blocks, which can be easily assembled without the need for mortar. It is often used for paving and landscaping projects.

These are just some of the common types of block making machines available in the market, and each type has its own unique features and advantages depending on the specific production requirements.

What are the advantages of using block making machines?

Using block making machines can provide several advantages, including:

- Increased production efficiency and speed: Block making machines can produce blocks at a much faster rate compared to manual production methods, which can result in increased productivity and faster completion of projects.

- Consistent and high-quality block production: Block making machines can produce blocks of consistent size and shape, which results in high-quality blocks that meet the required standards.

- Reduced labor costs and manual effort: Block making machines require minimal manual labor, which can reduce labor costs and minimize the risk of work-related injuries.

- Ability to produce different sizes and shapes of blocks: Block making machines can produce a wide range of block sizes and shapes, which allows for more flexibility in construction projects.

- Reduced waste and improved environmental sustainability: Block making machines can produce blocks with minimal waste, which results in reduced environmental impact and increased sustainability.

- Greater control over the production process and quality assurance: Block making machines allow for greater control over the production process, which can result in improved quality assurance and consistency in block production.

Overall, using block making machines can provide numerous advantages that can lead to increased efficiency, reduced costs, improved quality, and greater sustainability in construction projects.