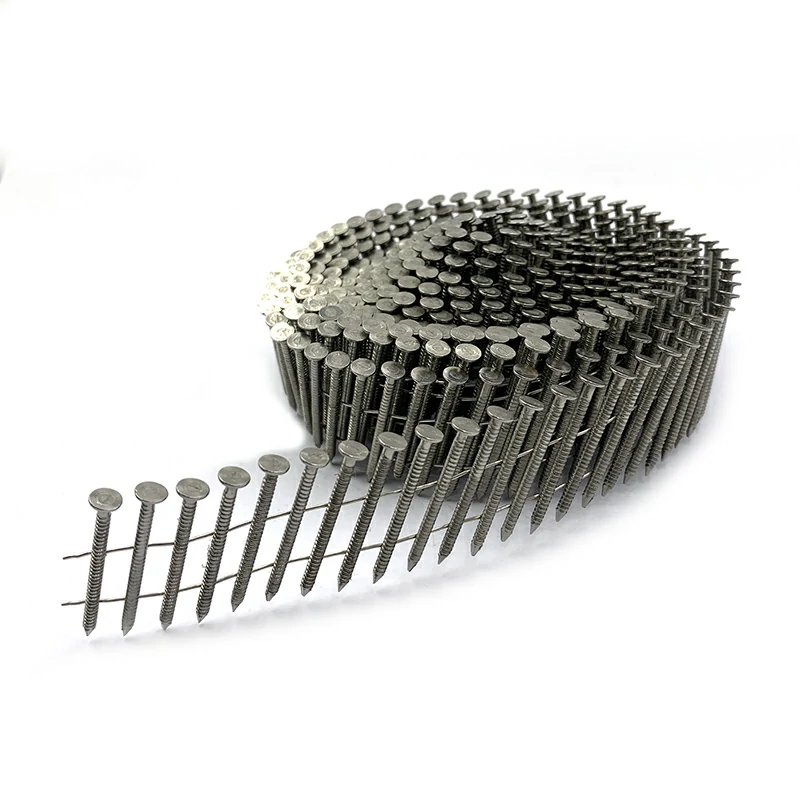

Stainless steel coil nails are a popular choice in construction, carpentry, and woodworking due to their durability, corrosion resistance, and high strength. These nails are designed to withstand harsh environments and provide long-lasting performance. In this article, we will delve into the composition of stainless steel coil nails, exploring the materials used in their construction and the properties that make them suitable for a wide range of applications.

Stainless Steel: The Foundation of Coil Nails

- Stainless Steel Alloys:

Stainless steel coil nails are primarily made from various stainless steel alloys. These alloys are composed of iron, carbon, and a minimum of 10.5% chromium, which imparts excellent corrosion resistance to the nails. Other alloying elements such as nickel, molybdenum, and manganese may also be added to enhance specific properties. - Corrosion Resistance:

The high chromium content in stainless steel coil nails forms a passive oxide layer on the surface, protecting them from rust and corrosion. This corrosion resistance makes them ideal for outdoor applications and environments with high moisture or chemical exposure.

Common Stainless Steel Grades Used in Coil Nails

- 304 Stainless Steel:

304 stainless steel is a common grade used in coil nails. It contains 18% chromium and 8% nickel, providing good corrosion resistance and excellent formability. 304 stainless steel nails are suitable for general-purpose applications in construction and woodworking. - 316 Stainless Steel:

316 stainless steel is a higher-grade alloy with increased corrosion resistance compared to 304 stainless steel. It contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. 316 stainless steel coil nails are often used in marine or coastal environments where exposure to saltwater or corrosive elements is prevalent.

Additional Considerations

- Coating and Finishes:

While stainless steel coil nails are inherently corrosion-resistant, additional coatings or finishes may be applied to enhance their performance further. Common coatings include electro-galvanized (zinc coating), hot-dipped galvanized, or stainless steel passivation. These coatings provide an extra layer of protection against corrosion or improve aesthetic appeal. - Design and Manufacturing:

Stainless steel coil nails are manufactured through a process that involves coiling a strip of stainless steel into the desired shape and size. The nails are then cut, formed, and sometimes heat-treated to optimize their strength and durability. Quality control measures ensure that the nails meet industry standards and specifications.

Can you explain the process of heat-treating stainless steel coil nails?

Heat treatment is a process used to modify the properties of stainless steel coil nails, such as their strength and hardness. The heat treatment process typically involves three main steps: heating, soaking, and cooling. Here’s a general overview of the heat-treating process for stainless steel coil nails:

- Heating:

The first step in heat treatment is heating the stainless steel coil nails to a specific temperature. The temperature is carefully controlled and depends on the desired properties of the nails and the specific stainless steel grade used. Heating is usually done in a controlled atmosphere or furnace to prevent oxidation or contamination of the nails. - Soaking:

Once the nails reach the desired temperature, they are held at that temperature for a predetermined period. This step is known as soaking or holding. The purpose of soaking is to allow the heat to evenly distribute throughout the nails, ensuring that the desired transformation occurs within the steel’s microstructure. - Cooling:

After the nails have been soaked at the specified temperature, they are cooled down rapidly or slowly, depending on the desired outcome. The cooling process is critical as it determines the final properties of the nails. Different cooling rates can result in variations in hardness, toughness, and other mechanical properties. - Quenching (Optional):

In some cases, a quenching step may be included in the heat treatment process. Quenching involves rapidly cooling the nails in a liquid medium, such as oil or water. This rapid cooling helps achieve specific properties by quickly transforming the steel’s microstructure. However, quenching is not always necessary for stainless steel coil nails, as they are already corrosion-resistant and may not require additional hardening. - Tempering (Optional):

After the initial heat treatment process, tempering may be performed to reduce any excessive hardness and increase the toughness of the nails. Tempering involves reheating the nails to a specific temperature below their previous austenitizing temperature and then cooling them in a controlled manner.

It’s important to note that the exact details of the heat treatment process, including temperatures, times, and cooling methods, can vary depending on the specific stainless steel grade, nail size, and desired properties. Manufacturers carefully optimize these parameters to achieve the desired balance between strength, hardness, and corrosion resistance in stainless steel coil nails.

Stainless steel coil nails are composed of stainless steel alloys, primarily containing iron, carbon, and chromium. The high chromium content provides excellent corrosion resistance, stainless steel coil siding nails making these nails suitable for challenging environments. Common stainless steel grades used in coil nails include 304 and 316, each offering varying degrees of corrosion resistance and strength. Understanding the composition of stainless steel coil nails allows for informed decision-making when selecting the appropriate nails for construction, carpentry, or woodworking projects.